Designing Out Waste

by Publication repost, on Sep 02, 2021

PUBLICATION REPOST l Stylus.com

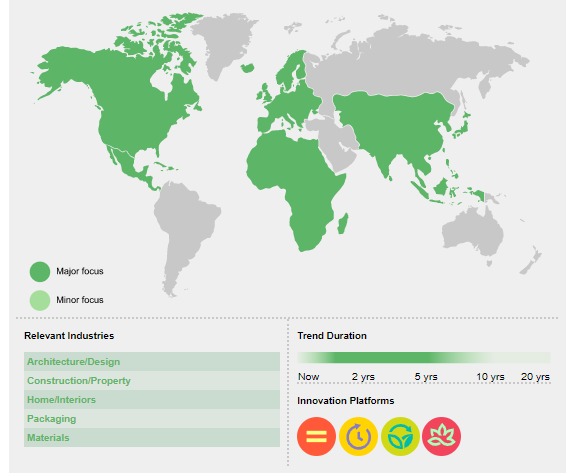

Waste is an issue that can no longer be ignored. As clever businesses begin to recognize that they cannot be seen as being part of the problem, we take a look at solutions making use of industrial by-products and recycling local refuse to forge a waste-free future.

No Waste Challenge

To help surface new ideas, the international creative platform What Design Can Do launched the No Waste Challenge, a competition initiated in collaboration with the Ikea Foundation. Responding to three briefs, designers proposed projects that either use fewer resources are made from more eco-friendly materials, or encourage responsible disposal. Awarded with funding and a development program, the 16 winners are pushing pragmatic solutions with commercial promise.

Solving Hazardous Waste

Innovative designers are working to not only remove hazardous pollution but transform it into something valuable – turning dangerous waste into constructive, even aspirational, resources.

Dissecting Resources: Waste products are often seen as useless, but designers are changing this by breaking them down into individual elements that are ready for reuse.The ‘ick’ factor is a major deterrent in the recycling of used baby diapers – but left as waste, they release methane and can also pollute water systems. In response, Kenyan company LeafyLife collects diapers and breaks them down using a benign organic chemical to extract clean-burning fuel and plastic, which is reprocessed into construction materials. By appreciating the different materials found within this undesirable waste, the company can harvest practical and valuable resources for other purposes.

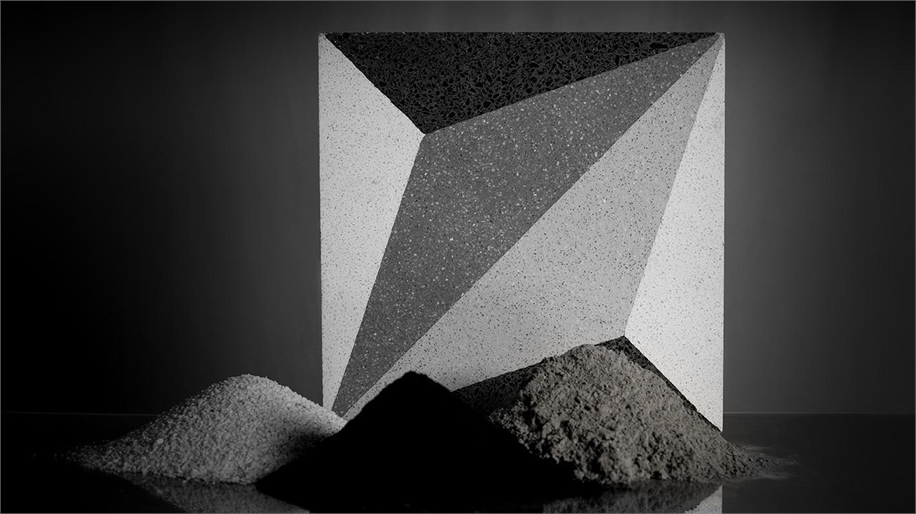

Indian company Carbon Craft Design applies this approach to carbon, a chemical that is increasingly polluting the air and causing illness around the world. It collects powdered carbon waste produced during tyre recycling (saving it from being burnt and entering the atmosphere), and mixes it with cement to create decorative hand-crafted tiles with a high-end finish.

Harvesting Local Waste Streams

Pressure is mounting on companies and designers to reduce their ecological impact and conserve precious resources. Waste arises as an essential tool to develop new products without further depleting the environment.

Recapturing Food Waste: The food industry creates a large amount of solid waste, with 25-30% of all processed fruits and vegetables discarded as by-products (UN FAO). Designers are tapping into this waste stream to distill accessible and abundant resources for product and packaging.Mexican designer Andrea Michael is recapturing the strong and fibrous leaves discarded from pineapple processing companies to develop a range of materials that can be used as locally sourced alternatives for rope, bioplastic, felt, and packaging foam. The project supports the readoption of local fibers, which have largely been replaced with synthetics, to reduce plastic pollution.

Kenyan company Nyüngü Afrika is similarly using pineapple waste and combining it with corn husk to create biodegradable female sanitary pads. The use of cheap waste fibers enables a lower price point that makes the pads affordable for low-income communities.

Dutch company Outlander Materials is reprocessing brewery waste into a non-toxic bioplastic that provides an eco-friendly option for single-use packaging. The material has exceptional barrier protection to withstand moisture and keep produce fresher for longer. Meanwhile, its semi-transparent appearance makes it a great sustainable stand-in for the plastic film windows commonly used for food packaging.

Materializing Circular Solutions

Producing no waste at all remains the best-case scenario, so designers are prioritizing natural materials that can break down responsibly at end of life.

Boosting Biodegradability: Mycelium, or mushroom root, grows over a base composite to harden into a sturdy yet biodegradable material. The mycelium feeds on and removes pollutants as it grows, making it an excellent additive to neutralize toxic waste.Mexican company Radial Biomaterials explores mycelium’s cleansing abilities by mixing it with polluted agricultural mulch to create alternatives for packaging as well as longer-lasting goods, such as lampshades and pencil holders, that can safely biodegrade.

Dutch company Loop also harnesses mycelium to create a coffin that can efficiently break down and process human remains to return nutrients to the soil. While quite radical in the application, the design proposes the perks of regenerative materials that not only create zero waste but also have a beneficial effect on the environment.